CARBON TECHNOLOGY

Chase’s philosophy is that you should work with industry experts when they can do something better than you. This is definitely true when looking at carbon production. We collaborate with the best producers to ensure we are always at the leading edge of technology. Our partners are constantly developing highly refined production techniques for other industries, meaning that we can select the best manufacturer to satisfy the varying needs of each frame we develop.

DESIGN

Bicycle design is a balancing act, juggling often conflicting requirements. A frame needs to handle accurately and be rigid to deliver all of the rider’ power to the road. However the frame also should deliver a compliant ride. It should be strong, yet light. And look good, too. Each project begins with a conversation, followed by several more, honing it down to what we call ‘a precise philosophy’. Although contradicting, and verging on pretentious, it helps us set a clear direction as to how we’d like a bike to ride in the prescribed circumstances. Then it’s time for the drawings. These then become plans and then computer models, which in turn are grown into 3D models. After more animated discussions on style and design sensibilities and most importantly, geometry, we call for prototypes to be tested in action.

CARBON PRODUCTION

Marketing has created a mystique around carbon frame quality; labels such as high tensile, high modulus, super high modulus and ultra-high modulus dominate the market. These terms relate to carbon’s properties, not its quality. Manufacturers are sometimes mentioned to add perceived credibility. Some brands say all carbon is the same, or that they use only ultra-high modulus fibers. In reality, high performance carbon frames must incorporate many different fiber types, each carefully positioned to achieve the right technical properties.

UNIDIRECTIONAL FIBER

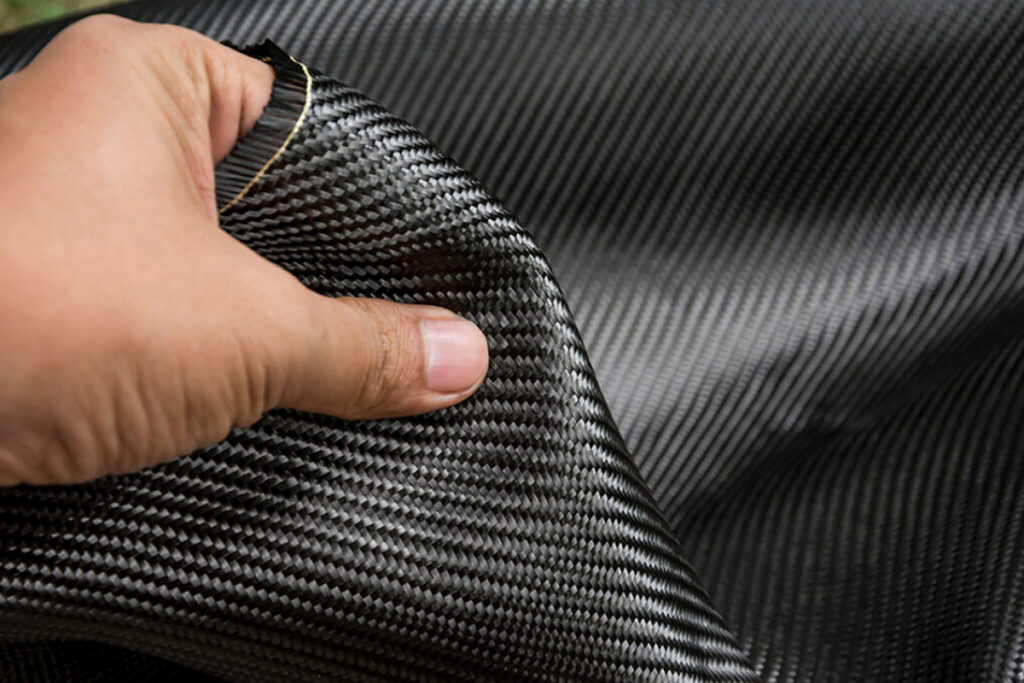

By now it’s almost common knowledge, the material we call carbon fibre is a combination of different types of carbon filaments bonded and held in place by resin. Just as there are different alloys of aluminium and steel, so there are numerous types of carbon fibre filaments. We use various grades of Toray materials combined in different ways. Unidirectional (UD) carbon fiber has all the filaments running the same way – it’s very strong in one direction, less so in others. Woven carbon has interlaced filaments positioned at 90 degrees to one another, making the sheet strong in multiple directions. It’s about using it where and when appropriate, all with the view to deliver a superior ride quality suitable to each and every bike in the range.