ALUMINIUM TECHNOLOGY

Chase has produced cutting edge aluminium frames for many years, continually refining our knowledge and developing new technologies.

Born from some of the best aluminium for building BMX race bikes, our special 7005-T6 SpeedLite alloy is the perfect blend for our Hydroforming process, giving our RSP frames the core strength needed to produce unmatched speed on the track, while keeping the overall weight of the frame down to a minimum. The way aluminium is treated and manipulated is as crucial as the grade selection.

There are a number of processes involved:

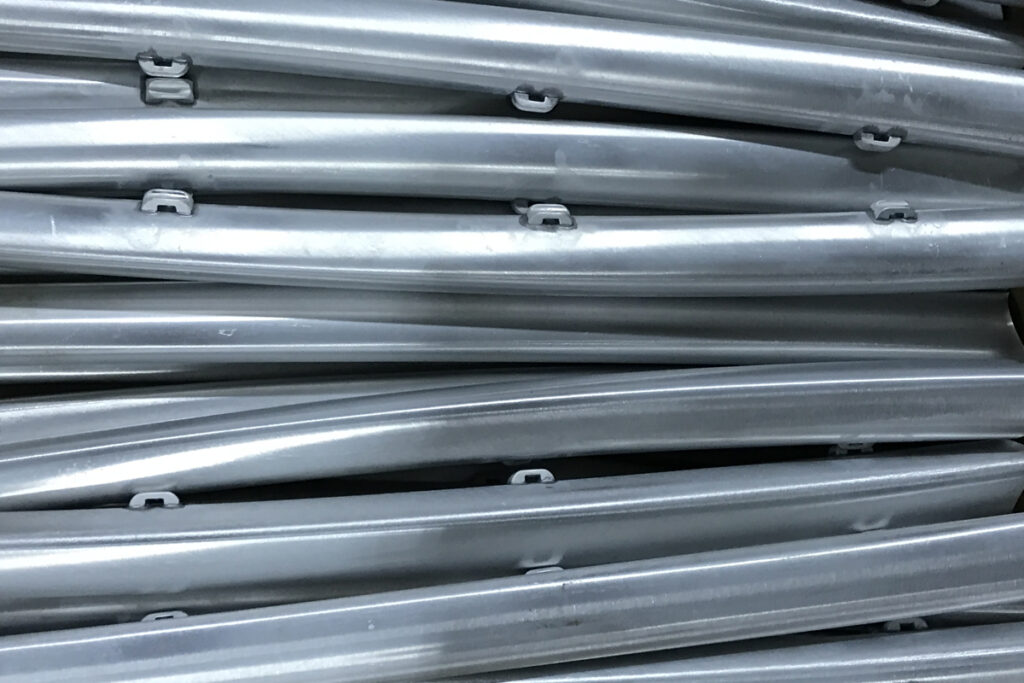

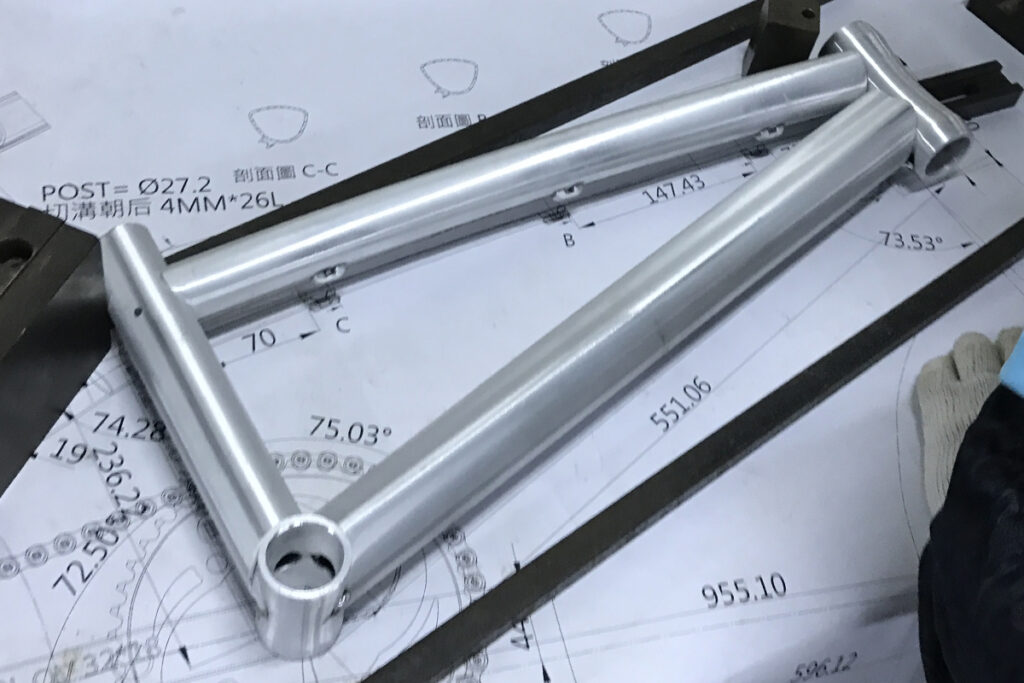

HYDROFORMING PROCESS

Hydroforming involves the insertion of tubes into negative moulds. A hot emulsion of water and oil is forced through at pressure, enabling them to be formed into complex shapes. Smooth welding, also known as double pass welding, refers to a second pass over the weld providing a clean organic look to the frame; at first glance, you will be convinced it is carbon, not aluminium.

TRIPLE BUTTED TUBING

Triple butting describes tubes with three different wall thicknesses along their length, optimising strength where it is needed but minimising weight in areas subjected to less stress. All our aluminium is heat treated. Frames are heated to very high temperatures (a T6 temper) then quickly cooled in water or oil to ensure the alloying elements don’t precipitate. Frames are subsequently heated to a lower temperature, artificially ageing and significantly strengthening them.

TAPERED TUBING

Tapered tubing to offer you the most durable, yet light weight products, to help you achieve optimum results. Our tapered items, use multiple thicknesses in the same tube, so the tube can be reinforced where needed with precision to help reduce stress areas where needed and lighten up the areas that don’t require extra materials. In aluminum the result are tube walls that eliminate stress points, boosting strength, reducing weight and improving fatigue life.